processbuild

Production Module

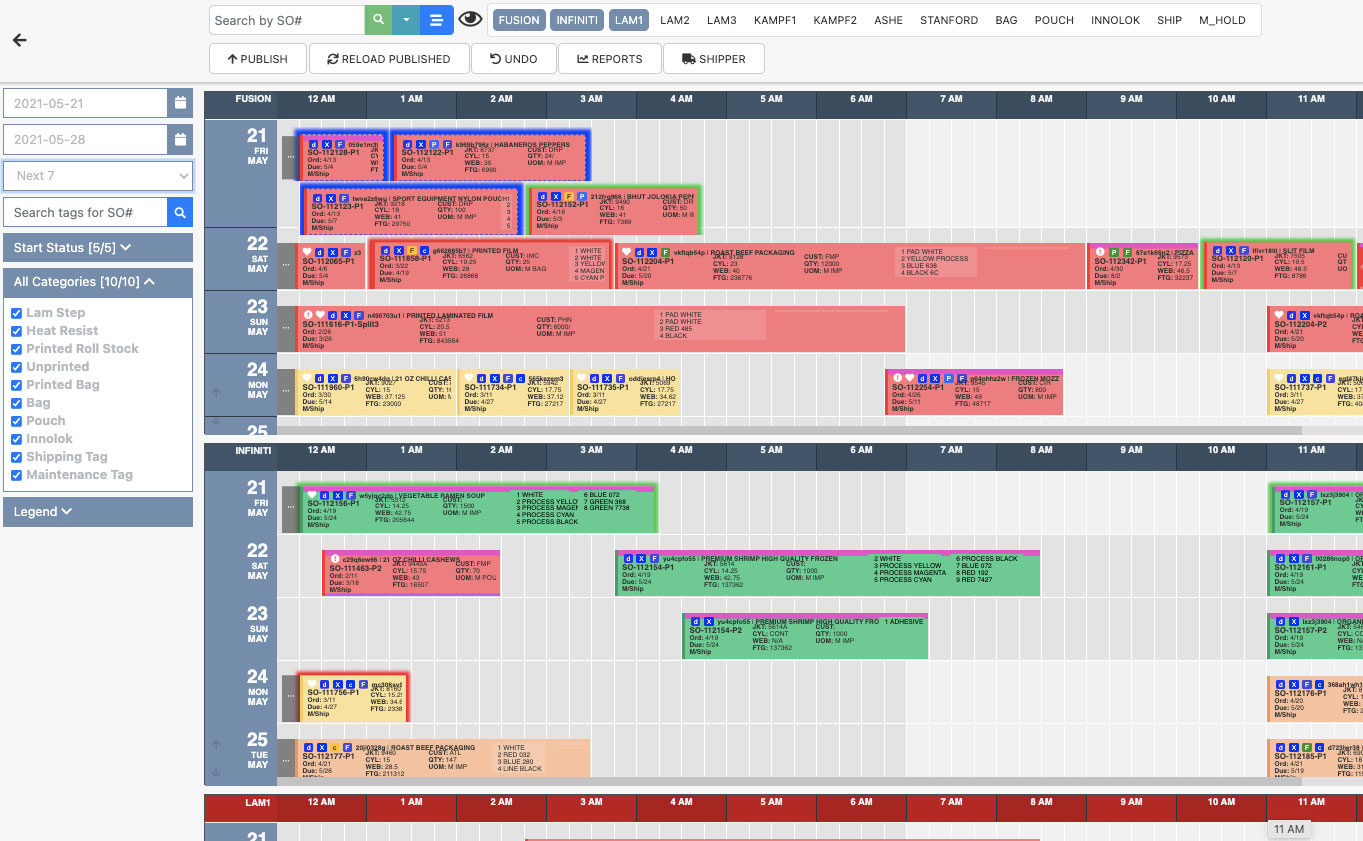

ProcessBuild’s Production management software enables you to gain greater control of your production process, increase throughput, and decrease lead time.

Benefits

of a Production Management Software

Increase production efficiency and process yield

Increase machine utilization to optimize the production process

Closely monitor costs at each step of the production process

Improve visibility and tracking of work in progress by implementing product traceability

Plan for contingent machine capacity to take on urgent/rush jobs

Reduce errors and downtime with 360-degree visibility of the production floor activities

Reduce lead time and improve throughput, increasing production output and finished goods turnover, thereby providing on-time deliveries

Increase throughput by reducing friction in the production process by resolving production issues in real-time

Identify cost reduction opportunities by measuring OEE (Overall Equipment Effectiveness), Total Effective Equipment Performance (TEEP), and Overall Labour Effectiveness (OLE)

Decrease rejects and defects by implementing strict quality control systems to reduce scarp

Reduce unnecessary downtime and maintenance costs by effective machine management and maintenance

Improve labour management and utilization by tracking labour productivity throughout the production floor

Features

Create user-defined workflows

- Map your workflows, production steps, and processes that best reflect your manufacturing setup.

- Use your own KPIs to track production efficiency and work in progress.

Manufacturing execution systems

MES solutions are the building blocks of intelligent manufacturing systems that integrate production management with other functional roles such as data collection and analytics, recipe management, process planning, and quality control.

HR management and shopfloor traceability

- Increase accountability and responsibility by giving the operators and staff access to data and information to resolve production issues independently.

- Create individual login systems and customized individual authorization systems for all operators to track labor efficiency and allocate tasks.

- Customized production plan and tracking for all employees

Quality Control Systems

The key to maintaining product quality is a company-wide commitment to quality control. Implementing quality control throughout the production process has become imperative to create a lean manufacturing system and minimize wastage while maintaining quality standards. ProcessBuild allows you to take complete control over quality testing and assurance by creating custom quality checks built into the production management system.

- Built-in quality control checks and parameters into the production process

- Assign quality checks to operators and processes

- Hold jobs that do not meet quality standards

- Quality tracking systems help you track & trace the production process for quality defects

- Create custom tests, and pass/fail parameters for quality tests

- Create quality policies and standard operating procedures (SOPs)

Process and Job tracking

Improve process flow by streamlining the production process and eliminating nonvalue added processes using tight production controls and lean manufacturing practices, reducing wastage and saving money.

- Create routing systems for products in the production process and track them via unique routing numbers/ Job ID’s

- Manage product and parts traceability throughout the entire process

- Track the value of work in progress and create rules for WIP limits

- Track all jobs in production using milestones throughout the process

- Implement lot tracking systems to monitor batch production using barcodes and batch numbers

- Check work order details with one click

Process Management

One of the critical features of our MRP-based production management system is process management. ProcessBuild’s manufacturing management system gives you the ability to track the performance of each machine or process separately to identify scope for improvement and cost savings. In addition, process management gives you a detailed look into the productive efficiency of a particular function and helps understand which processes are making or breaking your overall production efficiency.

- Badge scanning and login systems to limit and control system access

- View detailed time stamps for activities and operator actions in details

- Easily add process notes and record vital issues

- Record scrap type, scrap quantity, and reasons for scrap for each process or machine

- Manage consumed, rejected, and returned raw material

- Create supervisor acknowledgment list for process and quality checks before starting the process

- Report and process-related solve issues in real-time, reducing process downtime

- Create flags for essential job details that need to be viewed by the production manager or supervisor

- Record finished product data at the end of the production run

Product Management

ProcessBuild’s product management system allows you to:

- Create a multi-level bill of materials

- Record product details

- Track the movement of product through the production process

- Trace raw materials used to manufacture the product back to their source

- Assign quality checks and quality tests for individual products

- Improve recipe management

Get a Demo