processbuild

Scheduler Module

The production scheduler gives you a comprehensive overview and better control over production planning by improving the visibility of the manufacturing process. Production scheduling and manufacturing planning systems help optimize capacity utilization, reduce downtime, and plan for contingencies such as machine breakdowns or urgent jobs.

Benefits

of a Production Scheduler

Many MRP/ERP systems require you to purchase an entire turnkey solution, which often includes a large set of functions and modules that are not needed within your operation. With ProcessBuild, you can purchase and implement only the modules that you need. Most MRP/ERP systems are built on a closed-loop system and are unable to integrate with other systems you want to utilize for your day-to-day operations or additional functionality.

Create, share, and update schedules amongst

team members

Accurately estimate lead times to meet deadlines based on actual capacity.

Reduce manufacturing

lead time and

increase throughput

Reduce operational costs by controlling variability and by planning for contingencies

Features

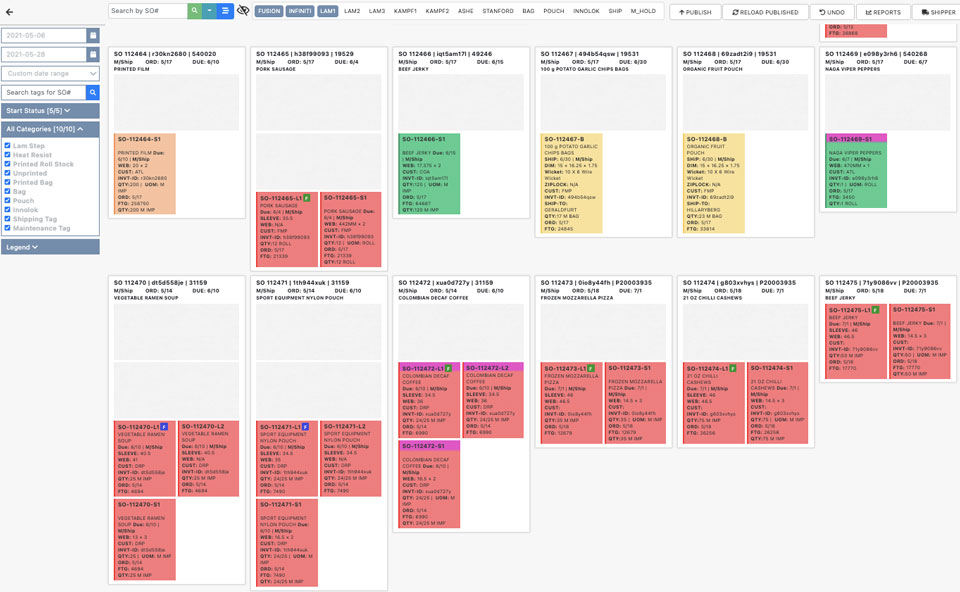

Digital Scheduler

Text-based scheduling systems like MS Excel or whiteboard schedules are prone to errors when manufacturing becomes extensive and complex. The digital scheduler makes it easy for production managers to view and manage production planning and scheduling at scale.

- Digital cards to create a Kanban-style scheduling system and optimize workflows

- Customized colour coding of tags conveys relevant information tailored to your specifications.

Creation of Custom Production Plans

The scheduler helps you easily create custom production plans while accounting for conflicts, redundancies, and capacity constraints.

- View urgent or priority jobs

- Plan and prioritize jobs by the delivery date or raw material availability

- Plan production runs for individual units or processes

- Create daily, weekly, monthly, or yearly production plans with an option to plan for contingencies

- Share the production plan across teams and silos to improve coordination and visibility

- View accurate expected job completion dates to keep sales teams informed and ensure on-time delivery

Master Production Schedule(MPS)

The master production schedule is also called the schedule of finished goods that the company aims to produce over a certain period. ProcessBuild’s scheduler helps automate the MPS system by pulling data from different silos like marketing, sales, business strategy, demand planning, and current demand to identify the aggregate demand level. MPS helps define all costs and resources needed to meet the total manufacturing demand by creating a detailed list of all jobs per production quantity and delivery dates.

- Apply forward or backward scheduling methods to anticipate production demand.

- Plan for independent and dependent demand

- Determine human resources, equipment, and raw materials needed to cover production demand

- Determine the availability and conflict of resources and raw materials needed for production

Our MPS system helps define all costs and resources needed to meet the manufacturing demand, current orders, and projected balances by converting the data to a production plan.

- Forward & Backward Scheduling

- Determine the availability and conflict of resources and raw materials needed for production

- Synchronize all resources to define priorities and fulfil orders efficiently

- Determine human resources, equipment, and raw materials needed to cover production demand

- Ensure optimum inventory levels with real-time inventory updates

- Independent and dependent demand planning

- Workforce planning

Forecasting

The production scheduler enables you to create accurate forecasts, capacity planning, and sales analysis. These forecasts will help you make critical business decisions related to throughput, resource requirements, revenue, and profitability.

- Create production forecasts based on past production runs and data.

- Perform sensitivity analysis

- Explore “What If” scenarios

- Determine the materials needed in the future based on past job data and performance

- Links to shipping to review forecast accuracy and adjust the forecast accordingly

Production scheduling

Scheduling takes a deeper dive into the production plan and helps you answer questions like which machine will be running on different shifts, days, and weeks? Who is going to operate each machine each shift, day, and week? What are the necessary ingredients, when are they needed, and when and in what quantity should they be ordered? ProcessBuild’s production scheduling and controlling systems help you:

- Define production quantity at the SKU level instead of at a family level, get more control of the production process.

- Allocate SKU production at a machine level

- Define inventory requirements at the SKU level

- Schedule shifts according to production needs

- Assign operators and other staff to production operations

- Add notes to orders to be reviewed by the staff

- Easily reassign tasks

Perform batch scheduling and lot breakups

Maintenance Planning

ProcessBuild’s maintenance planning tool enables you to plan and execute machine maintenance with easy. It helps you determine what type of maintenance needs to be performed, when it needs to be performed and what parts, components and skills are needed to perform the tasks.

- Create maintenance tags with a few clicks

- Create a maintenance program

- Schedule preventive maintenance for individual machines

- Pull real-time reports of machine issues and errors

- Maintain a spare parts inventory for parts that are frequently replaced.

Drag & Drop User Interface

The scheduler interface is designed to ensure maximum usability for all users, irrespective of their skill level or technical knowledge. As a result, anyone at the company can use the system without costly training or certification of employees.

- Schedule tasks through simple drag-and-drop of visual task tags onto the desired processes or machines.

- Adjust for downtime, job change over time, and required maintenance automatically.

- Lock important task tags in place to ensure that they cannot be moved or rescheduled automatically to accommodate other tasks.

- View the production status of task tags automatically (e.g., ready for production, production started, completed, aborted)

- View any number of custom flags on task tags to show the status of the job at other departments (e.g., materials received, paperwork ready, Quality Assurance passed, etc.)

One-click SO to MO conversion

One-click conversion of sales order to production/manufacturing order. Automatically create purchase orders for raw materials to fulfil recurring jobs based on past consumption, and create procurement guidelines against the BOM.

Production Planning/Manufacturing planning

The scheduler helps optimize production planning and control to ensure optimum time, material, workforce, and machine utilization. It provides the means to ensure smooth operations by reducing errors, delays, and bottlenecks. It accounts for the manufacturing process on a higher level to plan the production of finished goods. It enables you to map out the entire process from procurement of raw materials to the production and shipping of finished goods.

- Create a Bill of Materials to help visualize a comprehensive list of components and subcomponents that make the final product

- Calculate the cost of resources required to execute a production plan

- Determine lot sizing and vacant capacity

- Calculate manufacturing lead time

- Get pre-production estimates of costs and lead time

- Accurately plan production based on the availability of raw materials or receipt of raw materials in the future to avoid bottlenecks and delays

Monitoring and management of production plan

ProcessBuild’s scheduler enables you to track the real-time progress updates and monitor individual job progress to ensure jobs finish on time and within budgets.

- Increased visibility into delays, bottlenecks, and production issues that cause delays in production plans

- Book production output from previous workdays

- Live update on job status

- Live shop floor-level job status overview

- Task level control for monitoring and altering production plans based on delays

- Address production issues in real-time to minimize disruption

- Centralized production control for a better overview of the available capacity to plan for rush orders and urgent manufacturing requirements

Creation of work orders

Create, alter, and manage detailed work orders or pull work order information from legacy databases to create digital job cards with all the job information needed for the manufacturing process.

Estimation of lead time and material costs

ProcessBuild’s manufacturing planning system helps automate manufacturing cost calculations based on the bill of materials and other resource consumption. In addition, identify delay risks associated with raw material supply lead time to account for vendor-based risks.

Capacity Planning

Capacity planning is a crucial element in production planning and is often performed in isolation from other production planning activities due to its complexity. The ProcessBuild production scheduler helps integrate capacity planning within the production planning process to improve capacity utilization and minimize downtime.

- Perform finite or infinite capacity planning

- Facilitate capacity loading

- Manage Capacity Constraints

Machine Planning & Scheduling

Machine scheduling is an essential step in effective capacity utilization. ProcessBuild lets you customize the scheduler to your machines. You can define and work with machines flexibly to fit into your processes as any unit of production resource or processes: a physical production machine, a range of machines working in parallel, a step in the production process like QA or shipping. For example, in machine scheduling, you can:

- Allocate jobs to individual machines

- Flag issues with machines or jobs

- Plan for machine downtime and maintenance to avoid disruptions

- Implement machine changeover time within the scheduler to account for mandatory buffers between jobs changes

- Follow the production progress in real-time

Get a Demo