processbuild

Traceability System

Due to rising safety standards and compliance regulations, traceability has become one of the most pressing issues for manufacturers. ProcessBuild comes equipped with an end-to-end traceability system that can track all processes from procurement and allocation of raw material to production and shipping of finished goods. Our traceability system will help you understand what was produced by whom and what resources are used during the production process.

Benefits

of an Traceability System

Get a better understanding of the cause of product recalls

Visibility into batch level when a quality defect was first introduced into the production process

Get in-depth visibility into your production process to identify opportunities for optimization, improve and cost-saving

Improve quality, compliance, and efficiency through real-time visibility into operations facilitates root cause analysis

Implement a continuous improvement system to improve quality and save costs

Features

Process Tracing

- Process tracing enables you to track the movement of raw materials, work in progress, finished goods, and rejected goods through the production process

- View the details of all processes that a product went through.

- Improve production life cycle visibility and identify stages that contributed to the defect in a finished product.

- Perform value stream mapping by analyzing the manufacturing process to improve value generation.

End-to-end and inventory tracking software & Materials traceability systems

Our inventory tracking feature helps you track the movement of inventory throughout the manufacturing process.

- Track issued, process and returned raw materials throughout the production process

- View details of unprocessed and processed raw materials moving through the production floor

Lot Traceability

- Our lot tracking software lets you easily monitor batch manufacturing by creating serial numbers for lots and sub lots to

- Track the allocation of lots of raw materials.

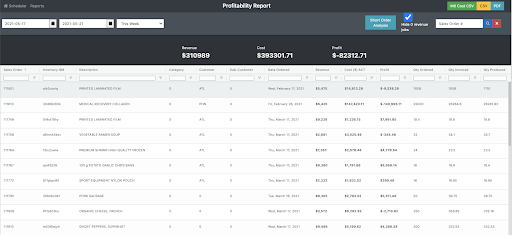

Traceability Reports

ProcessBuild’s traceability system uses a unique identification number to track a product’s movement through the production process. The report provides detailed information about the manufacturing steps the product went through, identifies the materials used in manufacturing the product, and the staff who worked on a particular process.

- Pull traceability reports using sales order or work orders numbers to view the status of the job.

- Get an overview of the finished goods journey through the production process

- Get details of all raw materials used for the production of the product

- Cross-check quality measures and quality checks for the finished products.

- Retrieve information about job wastage and the reasons behind the wastage to improve the yield for recurring jobs.

Product Traceability

- Backtrack products through their operational steps

- Perform a root cause analysis for quality issues and defects to see where the production system failed to meet quality standards and its reason.

- View information about the batch of raw materials used to manufacture the finished product and traceback using serial numbers to the supplier of the raw material

Wastage/scrap tracking

ProcessBuild’s traceability software enables you to track scrap generation at each production stage and helps to analyse the causes behind scrap generation.

Job Tracking

ProcessBuild’s manufacturing job tracking software lets you track in-progress jobs by clicking on the work order to get details of the status of the job and movement of the product through the manufacturing process

- Get real-time updates of job changes and issues as they get flagged

Cost Tracing

- Record costs at each step of the manufacturing process

- Track cost and profit centres of the production process

- Identify the process that contributes to the increased cost of loss-making jobs.

Production Tracking Systems

Production traceability is the key to identifying production and engineering-related issues on the production floor. ProcessBuild’s production tracking system enables you to track issues and problems throughout the production floor by giving the operators the ability to raise the problems in real-time and report any production interruptions.

- Track jobs and production progress through a production tracking board.

- Implement production tracking systems to control wastage and implement lean manufacturing principles

Get a Demo